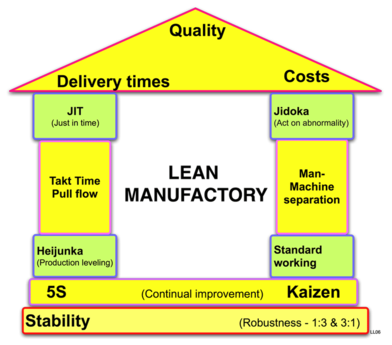

Lean-based system as made famous in Japan.

Michael I. Harrison, Ph.D., of the Agency for Healthcare Research and Quality, writes in NEJM Catalyst about the limitations of Lean-based approaches to healthcare institutions’ management.

He writes that “according to current research, Lean promises more than it has delivered. It is possible that published research studies are lagging practice, where there are some reports of Lean-driven breakthroughs in quality and value and even Lean-based culture change. But a positive publication bias may actually be leading the research literature to overestimate Lean’s potential.’’

Among his other observations:

- “To ensure appropriate care for chronically ill patients, and to promote population health, organizations need to redefine some traditional operating objectives and performance standards and develop new or radically redesigned care processes, such as team-based primary care. As Lean experts and users concentrate on making current processes more efficient, they may devote insufficient attention and energy to developing new goals and care delivery designs.

- “Except in tightly integrated systems, coordination of medical care requires cooperation across fragmented medical services. Health promotion calls for joint action by medical, social, and educational services. It takes time and concerted effort to build teams that bridge boundaries between care sites and entire organizations. But Lean projects typically rely on teams made up of members of the same organization, who already share objectives and operating assumptions.

- “Radically transforming taken-for-granted assumptions, values, and work procedures goes far beyond targeting selected processes for improvement. To change culture, leaders must articulate an overarching organizational change strategy and align diverse programs and improvement initiatives with that strategy. Strategic and behavior change must be implemented and reinforced through the appropriate use of performance measures, incentives, training, and staffing. Lean thinkers call for culture change, but popular Lean improvement techniques alone do not provide sufficient change levers to promote it.’’

To read Mr. Harrison’s article, please hit this link.