Memorial Health Center, in Springfield, Ill., the flagship of Memorial Health System. Also, see graphic at the bottom of this piece.

Charles D. Callahan, executive vice president and chief operating officer of Memorial Health System in Springfield, Ill., and Todd S. Roberts, vice president for quality and safety of Memorial Health System, write in a Hospitals & Health Networks piece about how the system implemented change to deal with the Affordable Care Act and other changes in the roiling healthcare sector.

They noted that the typical organization “squanders the equivalent of 30 percent of annual gross revenue due to defect-producing practices and overutilization of resources.”

They wrote: “{W}e determined to re-engineer our structures and processes as these are the necessary precursors to outcomes. We also recognized the need to find new ways to engage with our medical staff, and ultimately inform the training of next-generation physicians and health care professionals, to build a sustainable path.

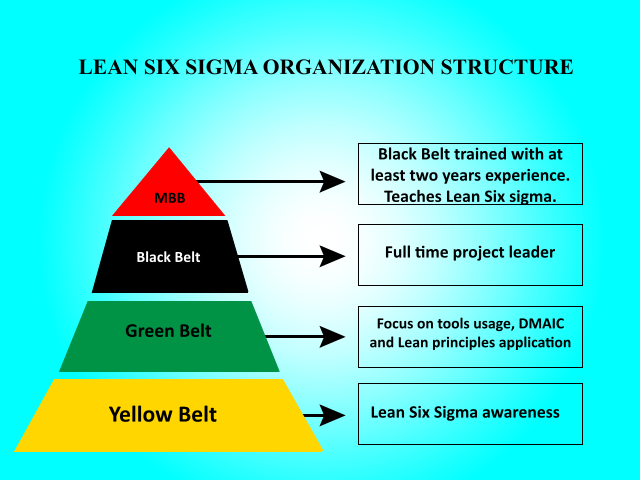

“In response to these imperatives, we modified traditional administrative structures to better partner with high-influence physicians (i.e., “silverbacks”) via dyadic relationships and team roles and to identify and prioritize high-value opportunities. We then adopted Lean Six Sigma, a rapid-cycle, data-driven process change methodology from industry that produces quality, safety, service and cost benefits that matter to stakeholders.”

Lean Six Sigma is a methodology that relies on a collaborative team effort to improve performance by systematically removing waste. See graphic below.

“Six years later, over 300 Lean Six Sigma improvement projects yielding nearly $30 million in positive financial impact have transformed the Memorial culture,” the two executives write. “Today, our approach is known as “The 30/30/30 Solution”: in each of the last five years, we have trained and certified 30 percent more Lean Six Sigma process change experts (“belts”), completed 30 percent more projects, and achieved an average project improvement of at least 30 percent on any project undertaken.

“Projects have spread to all areas of the organization: clinical, financial, service, production, facilities, inventory and workforce management. ”

To read the whole piece, please hit this link.